Why Container Devanning Is Important

Streamlining Global Logistics with efficient Devanning.

Container devanning, the unloading and unpacking of cargo from shipping containers, is the backbone in the global supply chain. Its efficiency directly influences supply chain optimization, reducing lead times, cutting storage costs, and enhancing logistics performance. However, the process is not without its challenges.

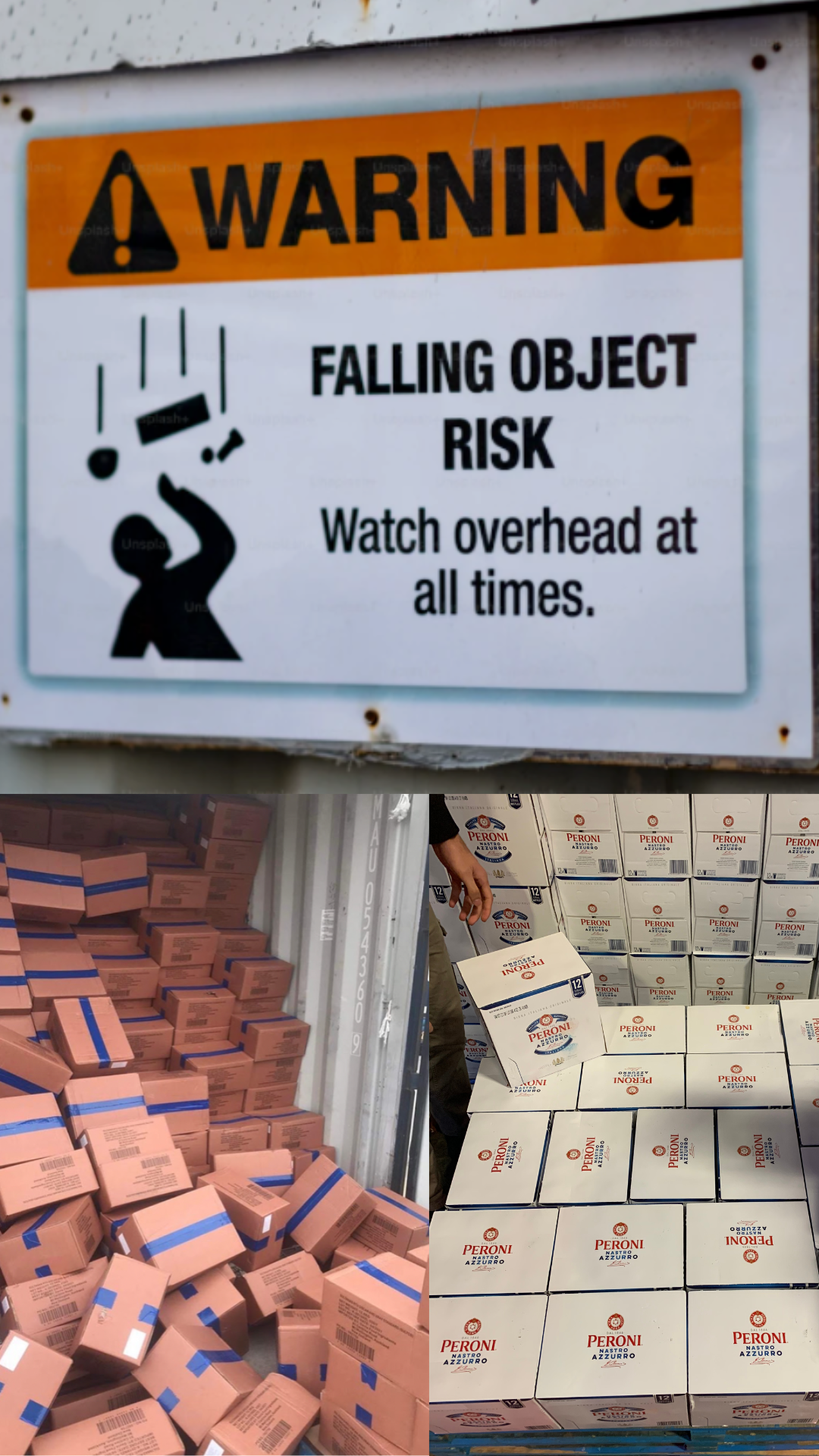

Cargo diversity, varying container sizes, and safety concerns pose significant hurdles. Containers often house an assortment of products, from fragile cargo to perishable goods, necessitating specialized handling expertise. Different container sizes, such as 20-foot and 40-foot variants, demand adaptable strategies for the devanning process. Ensuring the safety of both cargo and workers is paramount, requiring meticulous handling practices.

To overcome these challenges, adopting best practices is imperative. Pre-planning is essential, involving an understanding of cargo nature, resource allocation, and a well-defined timeline for devanning. Sorting and segregating goods into there Skus upon opening the container aids in efficient storage and distribution, as well as identification and removal of damaged items. Employing the right equipment, like forklifts and conveyor systems, accelerates the process. A trained well trained workforce familiar with diverse cargo types contributes significantly to a successful devanning operation.

In conclusion, container devanning is a vital link in the global supply chain, demanding careful planning, technological integration, and a skilled workforce to ensure efficiency. Many of our clients outsource their operation to us, MoreStaff - as we specialise in container devanning and have numerous trained teams of skilled staff ready to handle any container unloading job.

We'll find the right staff for you.

We'll help you find the talent you need, so you can focus on running your business.